Description

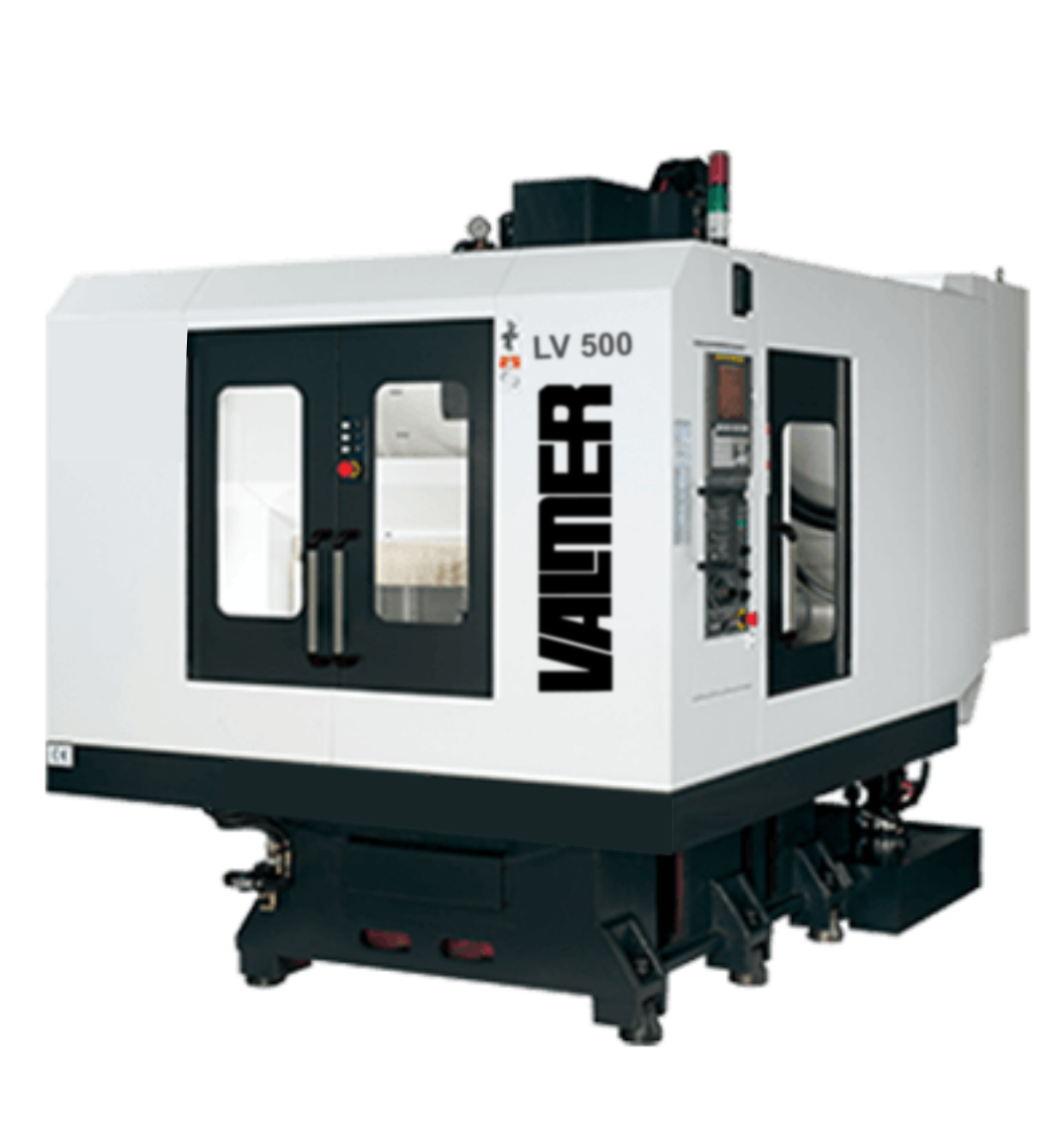

This 3 Axis Machining Center with Dual work stations, rotary worktables, and moving column structure allows operator to effectively reduce idle time needed to change workpieces during machining. Well suited for mass production. It is designed and manufactured by VALMER.

- HIGH SPEED SPINDLE

- HIGH RESPONSE SERVO SYSTEM

- HIGH SPEED 3 AXIS RAPID TRAVERSE

- DIRECTLY COUPLED SPINDLE DRIVE SYSTEM

- FULL-TRAVEL COLUMN, DOUBLE WORK STATIONS & HIGHLY RIGID MACHINE STRUCTURE

FULL-TRAVEL COLUMN STRUCTURE

Manufactured from high rigidity cast iron, the VALMER machine structures is computer analyzed for maximum rigidity, fast travel and heavy duty blocks for maximum feeding stability

DIRECT DRIVE SPINDLE

The directly coupled spindle eliminates power transmission loss to develop the highest efficient of spindle motor Spindle is mounted on four p4 high precision angular contact ball bearings combined with constant temperature device to provide outstanding richening rigidity.

Coolant Through Spindle (OPT)

Coolant flow is fed by a high pressure pump through the spindle and out the tip of the cutting tool, immediately reducing any heat at the cut point. This substantially increases the cutting efficiency while extending tool life, this system reduces thermal deformation and provides stable accuracy.