GC 600

NEWLY DESIGNED MACHINE STRUCTURE & SERVO SYSTEM

- Spindle Speed 8.000 RPM (STD)

- Spindle Speed 12.000 RPM (OPT)

- Rigid tapping 3.000 RPM

- Spindle nose taper BT-40

- 3 Axes rapid traverse X, Y, Z, : 36, 36, 36 m/min

- Fully enclosed head insolated electric cabinet.

- High speed mechanical ATC system

- Direcly coupled spindle drive system

Standard Acccessories

- Toolbox and tools

- Auto. lubrication system

- Spindle Air blow system

- Leveling bolts and pads

- Direct Drive spindle system

- Dual-color alarm light

- Dual electric cases. (Heat insulated)

- High speed arm type tool changer system

- Tool coolang system

- TFT LCD.

- FANUC / Mitsubishi Controller

Description

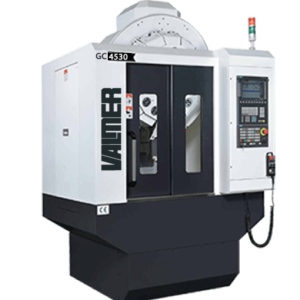

The CNC tapping center, designed and manufactured by VALMER, is your best choice in drilling and tapping work. The machine series employs a high speed traverse on three axes to significantly increase drilling and tapping efficiency. In addition, customers may select armless or arm type magazine according to machining requirement. The entire machine is ruggedly constructed to assure the highest machining accuracy.

- The structural parts of the machine are manufactured from high quality MEEHANITE cast iron, rib reinforced and stress released to assure it remains deformation-free year after year.

- Three axes slideways are mounted with precision linear ways. Extra-large span between ways. High feed rate and superior stability.

- Servo motor directly drives ballscrew, featuring high positioning accuracy without backlash problem.

BT-30 Direct Drive Spindle

Spindle speed 10000, 12000, 15000, 20000, 24000 rpm NBT with Two-Faces-Contact.

Coolant Through Spindle

Coolant flow is fed by a high pressure pump through the spindle and out the tip of the cutting tool, immediately reducing any heat at the cut point. This substantially increases the cutting efficiency while extending tool life, this system reduces thermal deformation and provides stable accuracy.

Z axis Telescopic Guard

To conform high speed traverse of Z axis, it provides superior protection for linear ways and extends their service life.

Linear Ways on 3 Axes

The X, Y, Z axis slidways are mounted with precision linear ways, fitted with great span between ways, showing maximum stability during high speed traverse. The ball type linear ways feature low friction coefficient and high positioning accuracy.

Large Capacity Coolant Tank with Casters

Sliding coolant tank can be pulled out easily while coolant pump with mesh filter take away cutting chips quickly.

Chip Auger

A chip auger is mounted at the center of the base, removing chips to the rear side of the machine easily. It makes chip disposal convenient.

X, Y Axis Telescopic Guard

The telescopic guards on X, Y-axis prevent chips or coolant from damaging linear ways.

“V” shaped telescopic guard on X, Y axis allows fast chip removal and high efficiency linear way protection.

| Table Size | 700 x 410 mm |

| Max. Table Load | 250 kg |

| X, Y, Z Axis Travel | 600 x 400 x 400 mm |

| Table to Spindle Nose | 120 ~ 520 mm |

| Spindle Speeds | 8.000 RPM |

| Spindle Taper | BT-40 |

| X, Y, Z Axis Rapid Feedrate | 36/36/36 m/min |

| Tools Capacity | 12 |

| Max. Tool Weight | 3 kg |

| Max. Tool Length | 250 mm |

| ATC Time | M 2.2 / F 3.2 (T-T) |

| Spindle Motor - FANUC | 7.5 / 5.5 kw |

| Spindle Motor - Mitsubishi | 7.5 / 5.5 kw |

| X, Y, Z Drive Motor - FANUC | 1.6 / 1.6 / 3.0 kw |

| X, Y, Z Drive Motor - Mitsubishi | 1.5 / 1.5 / 3.0 kw |

| Net Weight | 3550 kg |

| External Dimensions (L x W x H) | 1700 x 2750 x 2750 mm |